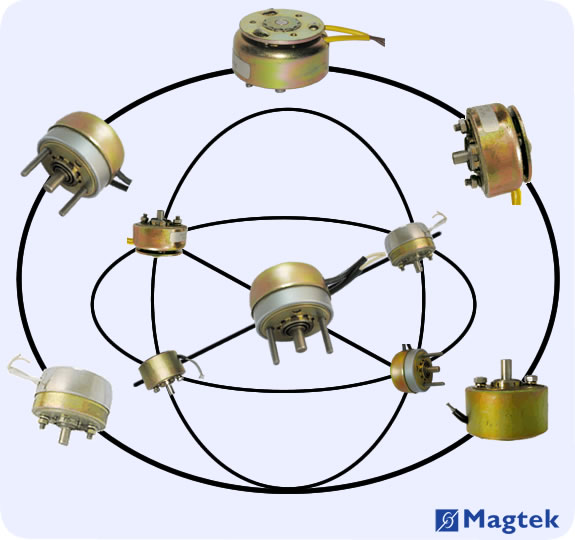

The designing idea of rotary electromagnet were actually originated from push-pull typed but with internal flat-angled plunger. Plus the tilt board design, electromagnet could transfer the linear motion into rotating style. There are three spiral cutting grooves on body and armature which is called “ball race”; ball race is mainly responsible for converting linear motion to rotary motion and also providing the bearing system to support the rotary action.

| Category | Insulation Class | Coil Temperature | Insulation Resistance | Insulation Dielectric | Range of ambient temperature | Lifespan |

|---|---|---|---|---|---|---|

| MTTR series | B Class (130°C) |

Under 100% duty cycle, temp. increasing range could up to 90°C |

100MΩ/DC 500V (Room temperature / Room humidity) |

AC 1000V, 50/60 Hz, 1Min (Room temperature / Room humidity) |

-20°C~+40°C | More than 2,000,000 |

| Category | MTTR series |

|---|---|

| Insulation Class | B Class (130°C) |

| Coil Temperature | Under 100% duty cycle, temp. increasing range could up to 90°C |

| Insulation Resistance | 100MΩ/DC 500V (Room temperature / Room humidity) |

| Insulation Dielectric | AC 1000V, 50/60 Hz, 1Min (Room temperature / Room humidity) |

| Range of ambient temperature | -20°C ~ +40°C |

| Lifespan | More than 2,000,000 |